UV Drain Relining

UV Drain and Relining

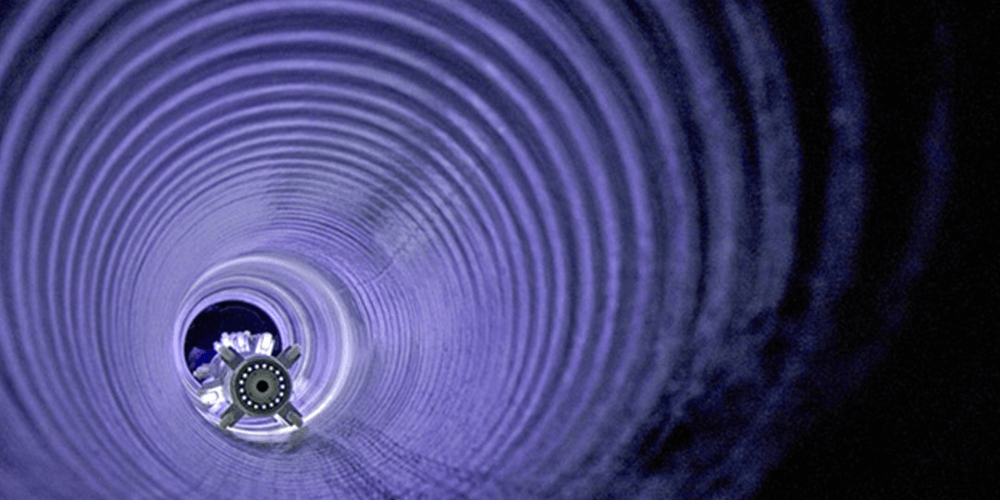

The STARLIGHT UV system, featuring a UV unit, three liner and several resin variants for the rehabilitation of sewers and pipelines from DN 80 to DN 300.

The are many benefits of using ‘No-Dig technology’ with UV Relining systems. The main benefits are the speed and quality of the repairs carried out, which involves inserting a liner with a special resin into a drain run or main sewer network. When the liner is in the correct position, we expand to form a perfect seal against the old drain wall. The UV lights are turned on and the curing process starts allowing us to quickly repair the damaged section of drain or sewer. Once the Liner is in place and if we have covered any junctions we can use our 360 degree robotic cutting equipment to cut out any Junctions that might have been covered during the repair, previously this would have meant having two liners from either side to prevent covering the junction and doubling the time it takes to complete the repair.

Time restraints for our customers is critical so when they need a repair done quickly traditional resin-based liners may not be the answer. The latest in UV CIPP (cured-in-place pipe) liner repairs means we now have the capability to dramatically reduce the time it takes to repair all types of drain runs in any length and sizes of drains and sewers.

We believe this method of relining and patch repairs create a permanent and long-lasting solution with minimal disruption to our customers.

The special resin is also styrene free, environmentally friendly and odour free making this a safer method for all concerned and gives a better quality repair whether its a patch repair or a large 50m repair!

About UV Drain and Relining

Time restraints for our customers is critical so when they need a repair done quickly traditional resin-based liners may not be the answer. The latest in UV CIPP (cured-in-place pipe) Liner repairs means we now have the capability to dramatically reduce the time it takes to repair all types of drain runs up to 50m in length and for all sizes of drains and sewers.

The are many benefits of using ‘No Dig’ UV Relining technology which involves inserting a liner with a special resin into a drain run or main sewer network. When the liner is in the correct position, we expand to form a perfect seal against the old drain wall. The UV lights are turned on and the curing process starts allowing us to quickly repair the damaged section of drain or sewer. Once the Liner is in place and if we have covered any junctions we can use our 360 degree robotic cutting equipment to cut out any Junctions that might have been covered during the repair, previously this would have meant having two liners from either side to prevent covering the junction and doubling the time it takes to complete the repair.

We believe this method of relining and patch repairs create a permanent and long-lasting solution with minimal disruption to our customers. The special resin is also environmentally friendly whereas the previous method was not!